Servicios al cliente

Sobre nosotros

Copyright © 2025 Desertcart Holdings Limited

⚙️ Unlock pro-level motor control with VIFERR’s powerhouse VFD!

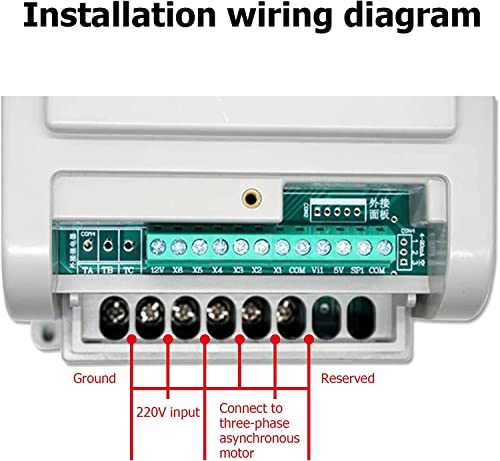

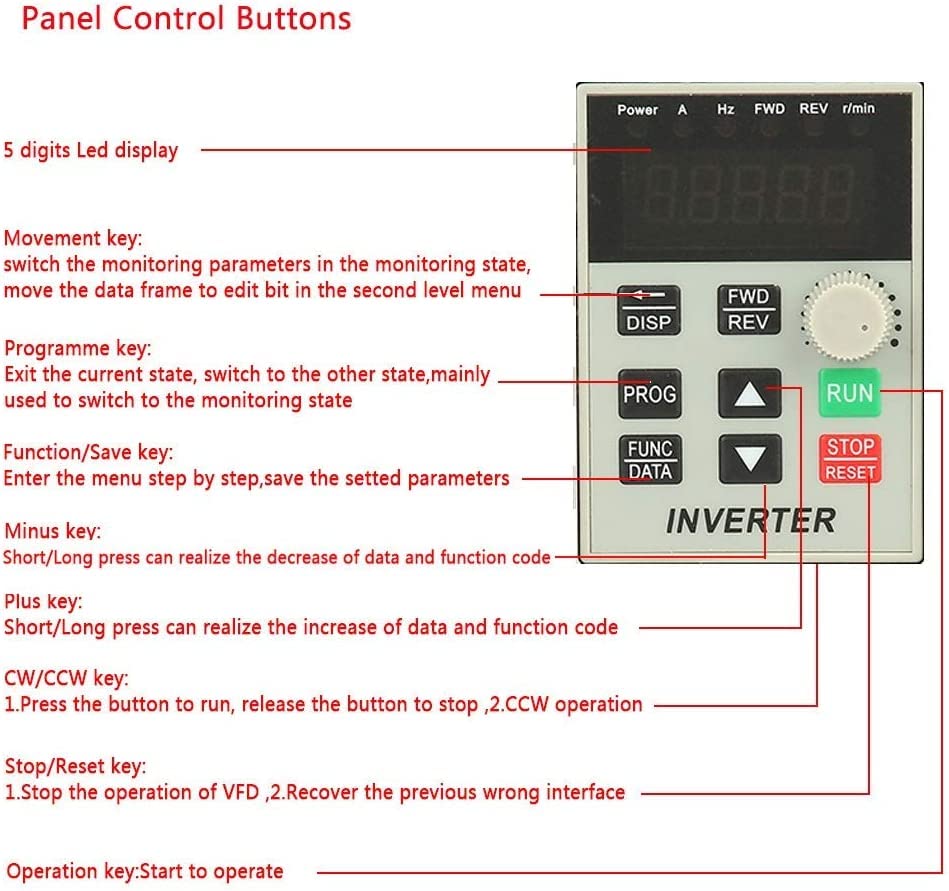

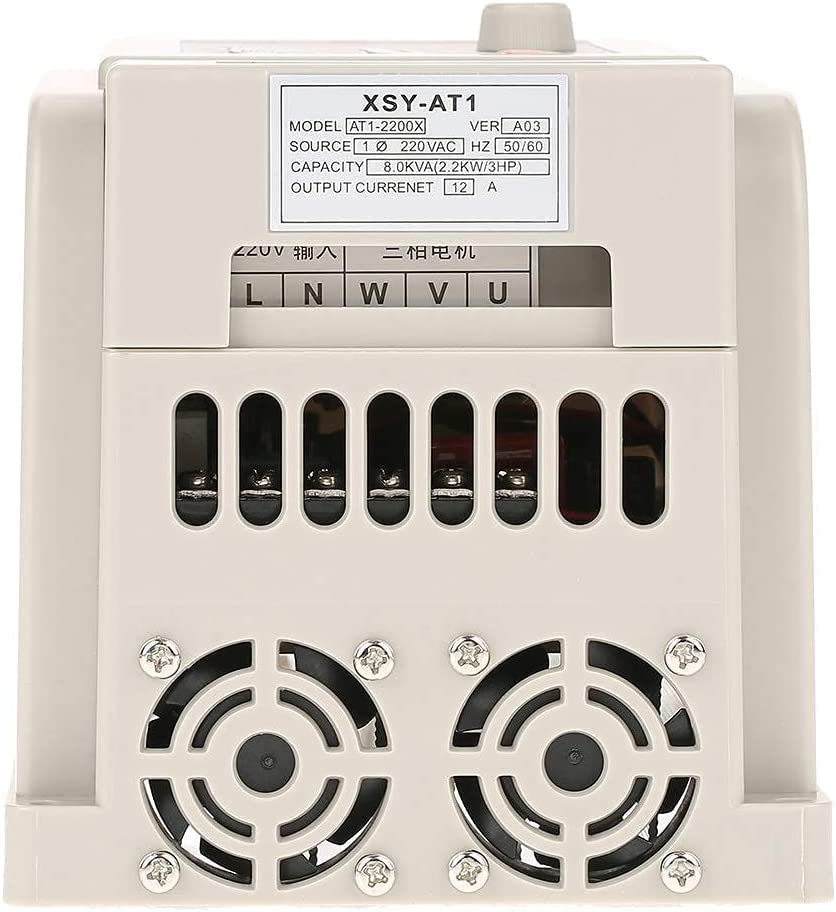

The VIFERR 2.2kW Variable Frequency Drive is a single-phase 220VAC speed controller designed for 3-phase AC motors. It offers a high maximum output frequency of 400Hz, ensuring wide speed regulation with stable torque. Engineered with advanced PWM control and a large heat sink, it delivers low noise, high reliability, and durability in challenging industrial environments. Easy to install with screw terminals, it’s the perfect upgrade for professionals seeking precise motor speed control and enhanced operational efficiency.

| ASIN | B0BGPJL271 |

| Batteries Required? | No |

| Batteries included? | No |

| Best Sellers Rank | 44,150 in Business, Industry & Science ( See Top 100 in Business, Industry & Science ) 181 in Motor Speed Controllers |

| Customer Reviews | 4.5 4.5 out of 5 stars (16) |

| Date First Available | 28 Sept. 2022 |

| Item Package Quantity | 1 |

| Item Weight | 1.33 kg |

| Item model number | VIFERRqko4zg0y1r |

| Manufacturer | VIFERR |

| Part number | VIFERRqko4zg0y1r |

| Product Dimensions | 120 x 170 x 150 cm; 1.33 kg |

J**W

easy way to add 3 phase in the workshop.

I purchased this to use with a 3 phase 1 HP TEC motor I have. It was to replace the one on my old milling machine which is making awful noises. By using a 3 phase Motor with this I can have variable speed on the mill without having to swap pulleys. A VFD (variable frequency drive) also retains the torque on the motor when changing speed. I have already got 2 of these units, one on my Myford Lathe and one on my CNC spindle and have never had a problem. Unfortunately since purchase my old Startright 352 bandsaw motor packed in last night so the mill project will have to wait and this will now be fitted to the bandsaw instead, that will have the advantage of giving me variable speed so with the right blade I should be able to cut metal as well (always try to look on the bright side when it gets expensive). Just means that I will have to buy another (and a motor) when funds permit for the mill. It is important that you get a shielded 4 or 5 Core 3 phase cable to connect the vfd to the motor (std mains cable from vfd to socket is fine) or you can get signal interference causing the motor to act up. This I purchase from a well known auction site for about £4 per meter delivered.

S**E

Works well but keep away from sensors becasue of electrical noise

works well and easy to understand and set. A lot of electrical noise and can interfere with other electronics

M**H

Good item

Good item and works well but instructions to program are virtually impossible to understand or follow due to the lack of written instructions. The only way it was possible to program was to reference YouTube.

K**S

Fast shipping, good product

I had to buy one of these inverters following an error done from chinese supplier on one of my machines. It was too expensive to change motor so I opted for one of these. Good price, fast shipping (i chose the fastest delivery and it was indeed) and the product, despite being chinese, is of very good quality. Worked wonders and its easy to wire and operate.

G**Z

Well made , well set out and easy to connect

It came well packaged and secured , good safety instructions , build quality is good , everything well labelled and straight forward to connect. Improves heat dissipation, and safety working in damp , humid, dusty conditions, it has good inbuilt safety features too. It's more compact and lightweight than i was expecting, instructions make it easy to set up and connect safely. Good value with the current discount, a good option.

R**A

Accurate

It gives you accurate reading. Quality of the item is good.

M**N

Great piece of kit

I use one for the vehicle lift and the other for the compressor. 2.2kW engines in both cases. Make sure you set it up right and it works perfect

L**B

INVERTER XSY-AT1 2,2 KW. Je l'ai installé sur un tour à métaux, équipé d'un moteur triphasé 750W. Cet appareil est très bien et simple à brancher et utiliser. La notice est en anglais, facile à comprendre, en voici un résumé : A la mise sous tension, affiche la fréquence réglée (le dernier réglage reste mémorisé) Touche « RUN » démarre le moteur Touche « STOP » arrête le moteur Tourner le potentiomètre pour changer la fréquence et donc la vitesse du moteur l’appareil est réglé en usine sur des paramètres standards Réglages des paramètres personnels : - appuyer sur la touche « PROG », P000 s’affiche, le dernier 0 clignote - flèches haut / bas pour se placer sur le programme désiré - touche « FUNC / DATA » pour entrer dans le programme - flèches haut / bas pour changer les valeurs - touche « FUNC / DATA » pour valider - touche « PROG » pour quitter la programmation P OO6 permet de fixer la fréquence maximum ( jusqu’à 400 Hz), par défaut réglé à 65 P OO7 permet de fixer la fréquence minimum ( jusqu’à 0 Hz), par défaut réglé à 0 voir la documentation pour la liste complète des paramètres

Trustpilot

Hace 3 días

Hace 2 semanas