Entregar a Panama

IPara la mejor experiencia Obtener la aplicación

Servicios al cliente

Sobre nosotros

Copyright © 2024 Desertcart Holdings Limited

⚙️ Turn your projects into precision masterpieces with power and style!

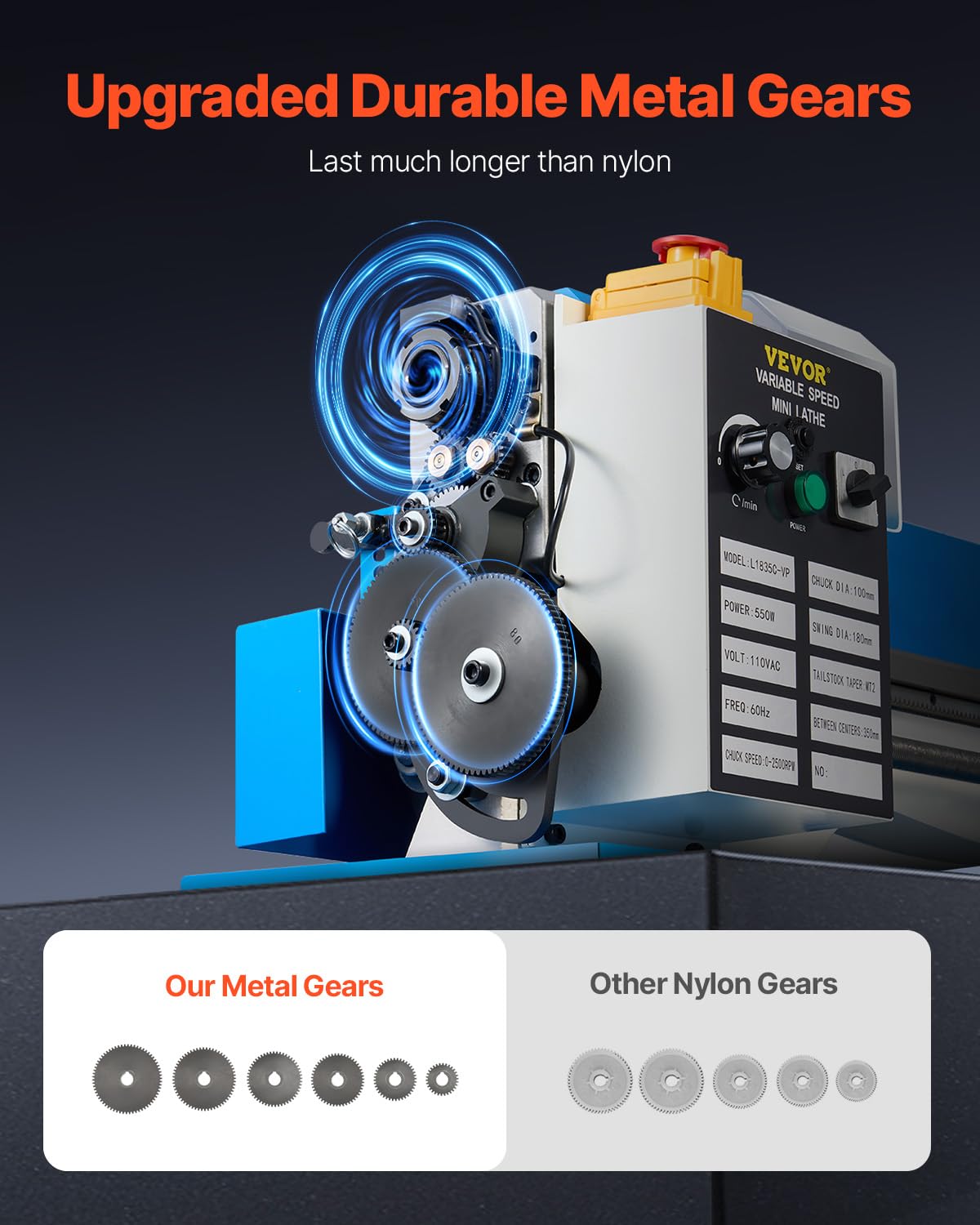

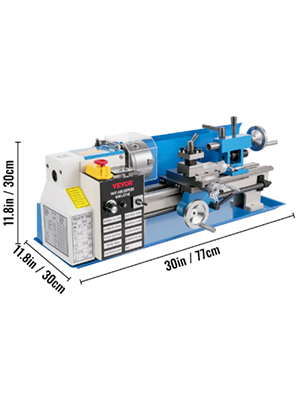

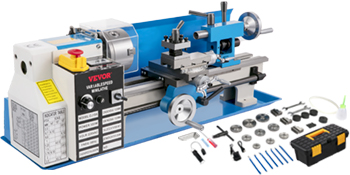

The VEVOR Mini Metal Lathe is a compact yet powerful benchtop machine featuring a 550W motor and variable speeds up to 2500 RPM. Designed for precision metal turning, drilling, and threading, it includes a digital display, durable aluminum handwheel, 4-way tool post, and an integrated LED light for enhanced visibility. Its upgraded metal gears ensure long-lasting performance, making it an essential tool for professionals and serious hobbyists aiming to elevate their metalworking projects.

| Manufacturer | VEVOR |

| Part Number | Mini Metal Lathe, 7"x14" |

| Item Weight | 142.7 pounds |

| Package Dimensions | 36 x 22 x 17 inches |

| Item model number | Mini Metal Lathe, 7"x14" |

| Size | 7" x 14"-550W |

| Item Package Quantity | 1 |

J**E

Nice Little Lathe at a Very Competitive Price!

Fast shipment from the vendor & very professional! I would recommend this machine to any of my friends. It's a great bargain for its size class.The machine arrived undamaged. Everything appears to be working as it should. Tolerances and runouts are as advertised and will not require much, if any adjustment. It's just a nice little lathe! Machines packed for overseas transport are usually covered with clear cosmoline or something similar. This unit was no exception. Expect to get several shop towels saturated wiping off the bulk of it, then use WD-40 to dissolve and wipe off any of it that remains. It's also a good idea to check the gears for detritis like wood chips and styrofoam that popped off the inside of the crate due to stapling of the crate at the factory to prepare the machine for transport. The stiff, brown grease on the gears in the drive train is for lubrication. As long as it's clean, there's no need to remove it. I plan to keep it well lubricated and use Vactra way oil on the various gibs, dovetails, and Morse tapers. Regular oiling of the lead screws and bearings that have oil ports is best practice and the machine should last for many years if you take care of it. Swarf it down at the end of every work session and when you expect to leave it sitting idle for extended periods of time.One thing that's often overlooked by newcomers is shimming the lathe bed. If you want to maintain tighter tolerances and minimize errors, shim the legs of the lathe bed to remove any twists. The rubber feet supplied with the lathe are not helpful in this regard. Bolt the lathe feet to a heavy bench and add shims. YouTube has several good videos showing how to do this.As to the several comments about the motor not running, READ THE INSTRUCTIONS!. There are several interlocks on this machine. The plastic cover over the lathe chuck has an interlock to ensure it is closed. The motor will not run if the cover is open. The Forward and Reverse switch on the front of the unit has to be set to the desired direction or the switch will trip out. And ALWAYS be sure to stop the machine when changing gears or directions. This thing isn't like a vehicle. Any time the gears or direction are changed, ensure the chuck is not turning!One other thing worth mentioning is that tachometer sensor under the end cover has to be close (but not touching) the left end of the lathe shaft. The small metal studs must clear the tachometer sensor. But if the sensor is too far away, the tachometer might register the rotational speed as something other than what it actually is. When I first turned on my machine, mine was reading about half the correct value. This is easy to fix by pushing the sensor a little closer to the shaft encoders, the small studs surrounding the end of the shaft.I have also seen a few people complaining about the lathe tools. These are brazed carbide cutters and need to be correctly sharpened before using. As with most brazed carbide cutters, it's up to the user to profile and sharpen them as needed before using them. You will likely also need to shim them in the tool holder to center them up to your workpiece. The lathe tool muti-tool holder will allow several cutter sizes. The ones in the included kit are 10mm x 10mm. If the cutter isn't lined up with with the vertical center of the workpiece, then watch some Youtube videos that explain how to do it. There is plenty of support for these machines on the Internet. If you have trouble finding videos, remember these all use similar parts that are made in the same factories in China.I agree that the multi-tool holder is a bit lacking and perhaps even more than a little clumsy. And depending on the metal you are working with, brazed carbide cutters might not be the best choice. They are typically used for cutting mild steel. Materials like high speed steel (HSS), titanium nitride, or cobalt steel cutter tools might be a better choice for other metals. It's just a budget tool holder with some general purpose tools for those who might not need anything better. There are lots of tool manufacturers with thousands of specialized tools available. Several recommendations are Shars Tool, Harvey Tools, and Tormach.There are several after-market quick change tool holders that will fit this machine with little or no modification. Remember, you are at liberty to add after-market parts and modify this machine as you desire. For small shop and hobbyist work, it's impossible to guess what every end user might need or expect. So watch videos, read books from the old timers, and ask questions. Someone will likely have a solution for whatever you may encounter. Also, remember that the larger the machine, the greater the cost for the tooling and work holding attachments. The cost of tooling and add-ons goes up exponentially with size of the machine. Many production shops that are trying to reduce turnaround time will expect more than the mini lathes and mini mills are capable of. If you expect the small machines to plow through the toughest metals with just a few passes, they just aren't capable of doing so. But most are capable of doing a decent job if you aren't in a hurry, take shallower cuts, use the right cutting tools, and don't have a long line of customers waiting.If you don't believe me, then look at what some of the so-called "model engineers" do with these things and even smaller machines of various brands. A good place to start is with the Home Shop Machinist books by Village Press, Inc if you are here in the US, and with lathe and mill books from Fox Chapel Books if you are in the UK or other countries. Amazon has both available.

P**N

Marginal Quality

Received in good condition, well packaged. All components were there, nothing missing. After cleaning the awful grease that covered everything and properly lubricated everything, I set in to make measurements and adjustments.The headstock runout was about 1thou, kind of expected for these cheap lathes. Ways were flat to about 1 thou after shimming and mounting to a heavy bench. The tail stock is absolute junk … it was 25 thou out of alignment. I could adjust the horizontal alignment, but the vertical was too high so nothing could be done to correct it other than machining the guide that sits on the ways.Unfortunately, the design is lame and the stock sits on an angle instead of sitting flat on the ways. To properly correct this, I’d need a 90deg chamfer bit for my mill but didn’t have one. I milled the opposite side to lower the stock so I could adjust it. I was able to align with the head stock to within 2-3thou. Total taper on a supported piece after turning it was still unacceptable. Getting a new tail stock.Yeah, I knew this would be a project, but didn’t expect the tailstock to be that bad. If you bought this and didn’t have a mill, this lathe would not be useable.I’m rating it 1 star so everyone is aware that if you buy this lathe you may not be able to get it in working order if you don’t have the tools and skills to fix it.There is truly NO quality control on this stuff so buyer beware.

B**N

Advice from a buisness owner using this lathe

Pros:CheapEasy to useStrong enough to cut Titanium with different carbides than includedThe automatic feed works greatVery durable and sturdy designCan run very fastOverall just a great machine that does as advertisedCons:Tailstock is a little weird, never is perfectly centeredThe tool post isn't height adjustable, I would recommend buying a different one to installThe torque applied to the chuck is constant but the speed will vary by about 150 rmp when cutting hard metals vs just spinning without cutting.The included tools are trash. Buy your own, especially a boring bar and parting tool^^^^^All these problems are fixable with about another $100 (with the exception of the speed variation)Takeaway:This lathe is worth your money, especially if you upgrade it. At such a low cost it has the power to cut very strong metals. Make sure to buy a different tool post and different carbides and your %100 set.Would strongly recommend it.I use this Lathe to make rings and wedding bands and it does the job!

Trustpilot

Hace 1 día

Hace 1 mes