Customer Services

Copyright © 2025 Desertcart Holdings Limited

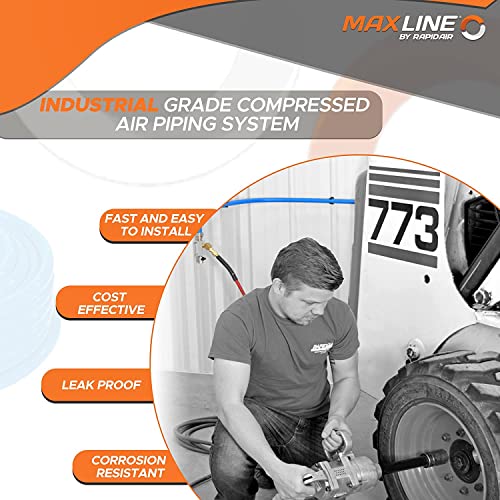

🔧 Elevate your air game — master your workspace with Maxline precision!

The Maxline M3800 Master Kit features 100 feet of durable 1/2-inch tubing with nickel-plated brass compression fittings, supporting up to 175 PSI and compressors up to 5 HP. Designed for easy installation and reliable multi-outlet air distribution, this kit is ideal for professional workshops and garages up to 2000 sq. ft., combining durability, efficiency, and versatility in one comprehensive package.

| AC Adapter Current | 10 Amps |

| ASIN | B00CZ7GTLU |

| Batteries Included? | No |

| Batteries Required? | No |

| Best Sellers Rank | #388,998 in Tools & Home Improvement ( See Top 100 in Tools & Home Improvement ) #1,360 in Air-Compressor Accessories |

| Brand | Maxline |

| Capacity | 6 load |

| Color | Plain |

| Compatible Hose Diameter | 0.5 Inches |

| Customer Reviews | 4.5 4.5 out of 5 stars (596) |

| Date First Available | April 21, 2009 |

| Global Trade Identification Number | 00094084380004 |

| Hose Length | 100 Feet |

| Included Components | Includes product as described |

| Is Discontinued By Manufacturer | No |

| Item Package Quantity | 1 |

| Item Weight | 2 pounds |

| Item model number | M3800 |

| Manufacturer | Rapidair Maxline |

| Maximum Horsepower | 5 Horsepower |

| Maximum Operating Pressure | 175 Pound per Square Inch |

| Maximum Power | 5 Horsepower |

| Metal Type | Mild Steel |

| Model Name | M3800 |

| Motor Horsepower | 5 Horsepower |

| Noise Level | 1 Decibels |

| Part Number | M3800 |

| Pattern | Argyle |

| Power Source | Corded Electric |

| Product Dimensions | 17"L x 17"W x 8"H |

| Recommended Uses For Product | auto racing |

| Special Feature | Sold by Speedway Motors |

| Special Features | Sold by Speedway Motors |

| Style | Traditional |

| UPC | 735090268787 094084380004 |

| Voltage | 1 Volts |

| Warranty Description | 1 year warranty limited warranty |

M**.

This kit is a great starting point.

Installed this along with several other additional components to run air drops at multiple locations in my barn/shop. Total install was about 150' and six drop down/outlet headers. A few multiple outlets headers at two of the locations and the reminder are the standard outlets that come with this 3 place kit. Overall installation was pretty easy, but did require some larger adjustable wrenches and some pretty good strength to seal the fittings, additionally, I recommend using Loctite 545 instead of Teflon tape to seal all the NPT connections. So far it's leak free and looks pretty good as well. The lines are a metal core with a polymer exterior. They come coiled up and getting them straight isn't the easiest thing to do, however with some patience and a good bit of space it's definitely possible to get them pretty darn close to straight (where needed) and curved (as needed) without the (my opinion) overly expensive tube straightening tool. Definitely think this kit is an improvement over the lower product line from them that is just plastic hose with pushin fitting - Have this in my attached garage, before building the barn/workshop.

R**R

I keep coming back to Maxline every time.

I just finished our 3rd installation of Maxline in our business and at my home shop and now I'm planning an expansion in the shop. I keep coming back to the Maxline product because it works, it's economical, it's easy to install & maintain and it looks great. All of our blue lines are installed on the outside of the sheetrock where they're easily accessible and we use the optional black plastic clips spaced anywhere from 2' to 4' apart. Our CFM requirements aren't very high so we've stuck with the 1/2" pipe size which contributes to the economy of our systems. At the business, some of the air machines are over 100' from the compressor and I wasn't sure if they were going to get enough air so I had planned to put in a header tank in the distant machine room to act as a ready reserve, but it was never needed. At the home shop, the most distant tire hose reel is 80' from the source and some of the spray equipment might need higher flow, so for the expansion phase I plan to complete the loop back to the source. In this way, air can travel both directions around the pipe to wherever there's a need. The attached pic shows this manifold, which comes with the Master Kit, and you can see the available 2nd outlet on the front that's plugged off for now. Tip: Use thick Teflon tape like Maxline sells (assuming they still do) and plumber's paste on all of your NPT connections. I like to fold the tape in half (easier if you use 3/4") and then make 2 wraps nice & tight right at the start of the threads. Then apply the paste, just a bit, around the tip of the threads and back about 1/4". I use the blue paper towel shop cloths and cut them into fourths, then fold those down to a small size and use them to clean off the paste around the joint--you can refold these little pieces a few times before tossing it and grabbing another one. If I had one suggestion for Maxline it would be this: Please redesign your fittings to be less restrictive. Yes, I understand the Bernoulli principle and the Venturi effects involved, but there's still some static pressure caused whenever you have a restriction in a flow tube. I realize that the fittings must go inside of the Maxline tubing and I just wish that these bits could be a little thinner through there. In some cases this will prompt people to jump up to the 3/4" or even 1/2" option but so far we're getting good service from our 1/2" system, at least until our CFM requirements increase. You may find some frustration with straightening the coiled tubing. I've worked it on the floor with a helper after cutting it to the proper length and I've also used Maxline's beautifully made aluminum roller system straightener. The device helps but not as much as hoped and frankly I think the design of the wheels could be improved. You can build your own using a plan that's available on Maxline's website but I've not tried it although I would probably do so if I hadn't bought this one on the assumption that it would work better than it does. Eventually though, you work on the tubing enough that you're ready to settle for slight straightness errors and then you install it and it turns out to be better than expected. If you work with a helper, you can make minor adjustments after the tubing is snapped into the clips and then you stand back and realize that it looks pretty good.

C**.

Easy to bend.

This does not leak. The pipe was easy to run and bend by hand. I had plenty of fittings to pipe three air drops. One of the brass 45 degree fittings split because I overtightened it. My shop 90 feet long total. I spaced all the drops roughly 25 feet apart. All on the same side and about 5 feet up from the floor.

E**O

Great kit, but lacks a few simple upgrades

If you're a normally handy person, this kit will come together quite easily. The downside to flexible pipes like this is that they're very easy to bend by mistake when you install them, so you have to come up with a way to hold elbows and "T"s when you tighten them up. I found that holding them with a pipe wrench was the best way, although a bit awkward when working overhead. To minimize this, I preassembled some of the trickier parts of the system before hanging them. I'd recommend that you plan ahead and preassemble as much as possible on the floor, that will save you quite a bit of time and effort. The threads on some of the fittings were a bit rough and felt like they were about to gall before they were tight enough, so I would also recommend that you lubricate them. I brushed on a small amount of bearing grease, and that made them much smoother. As a whole, the system was pretty easy to install without using much bad language at all. I actually bought some extra bits and pieces to make sure I had drops where needed, so I ended up with 7 drops and numerous "T"s and elbows. When I turned on the air I was ready to start chasing leaks, retightening fittings and everything else that usually goes with air line installations, but I lost less than 1/2 lb of pressure overnight when I tested it. This could just as well be in the compressor, regulator, auto drain, couplings or whatever, so I'm definitely happy with that part. Now for the not-so-good part: The outlet blocks are too thin. They're only 1" thick, so there's very little material left for the pipe thread on the front and the back. I can fully understand why they recommend thread tape AND sealant for the installation, since there's only about 3-4 full threads that can seal properly. The block is actually so thin that when you connect the air line, there's just barely room to turn the nut without the hex scraping against the wall. It doesn't leave you much space to turn the wrench either, so I decided to 3D print 1/4" spacers to make the lines easier to install. These blocks should really be 1 1/2" thick, that would ensure a good thread depth and it would make the installation easier as well. It would also be great if they had provided clips with the kit. You will definitely need them, and since the lines are so easy to bend you will also need a lot of them. The Maxline clips are a total ripoff at $16 for a bag of 10, so I used 1/2" PEX clips instead. They were only $6 for a bag of 25, so it sure wouldn't hurt if they had included a few bags of these in the kit. Really, the kit can't be installed without clips, so I sure don't understand why they don't include any to begin with. All in all, this kit was a very good value, and it sure beats struggling with hard lines when you're installing in a crowded workshop like mine. I would have given it 5 stars if it hadn't been for the outlet blocks and the lack of clips.

F**Z

Acabo de terminar hace pocos días el sistema de aire de mi taller en la casa, hasta ahora todo muy bien, un poco caro su precio, pero si lo vale; muy práctico su uso queda muy completo en mi taller y sobre todo muy facil su instalacion me quite de muchos problemas, en comparación con la instalación de un sistema de tubos negros o de cobre este es mucho mas sencillo y flexible de colocar, muy contento

B**R

excellent product, easy to install.

M**4

Installed it in my new shop. Went up easy and no leaks on the first pressure up!!

S**N

This is a great product. I found it easy to install, very easy to work with !

K**E

Easy to use, easy to install and great end result once installed. Would have been nice if it had a couple more T fittings, and adaptors for air couplers, and the clips to mount to the wall

Trustpilot

2 months ago

1 week ago