Customer Services

Copyright © 2025 Desertcart Holdings Limited

Desert Online General Trading LLC

Dubai, United Arab Emirates

🔩 Elevate Your Machining Game!

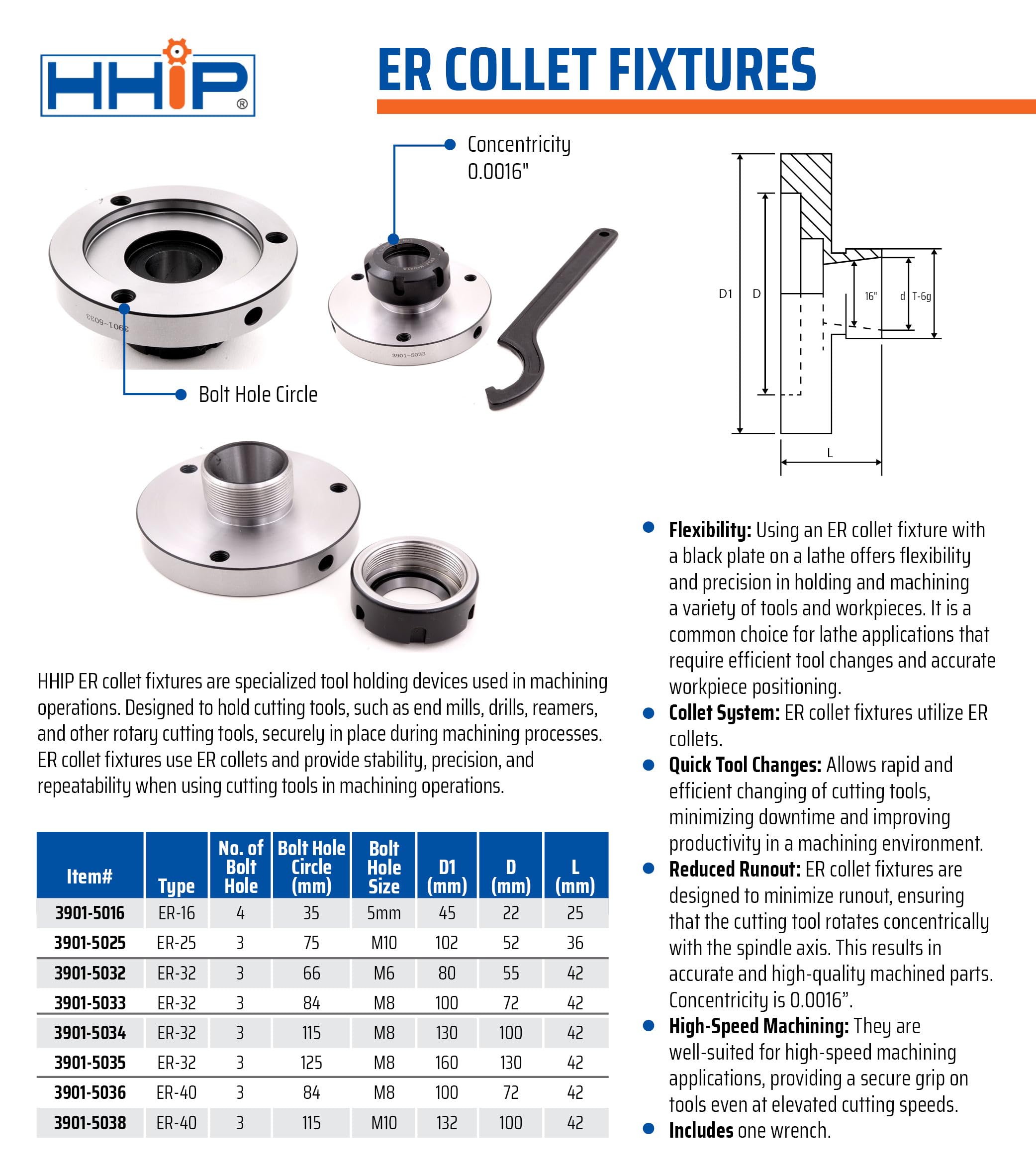

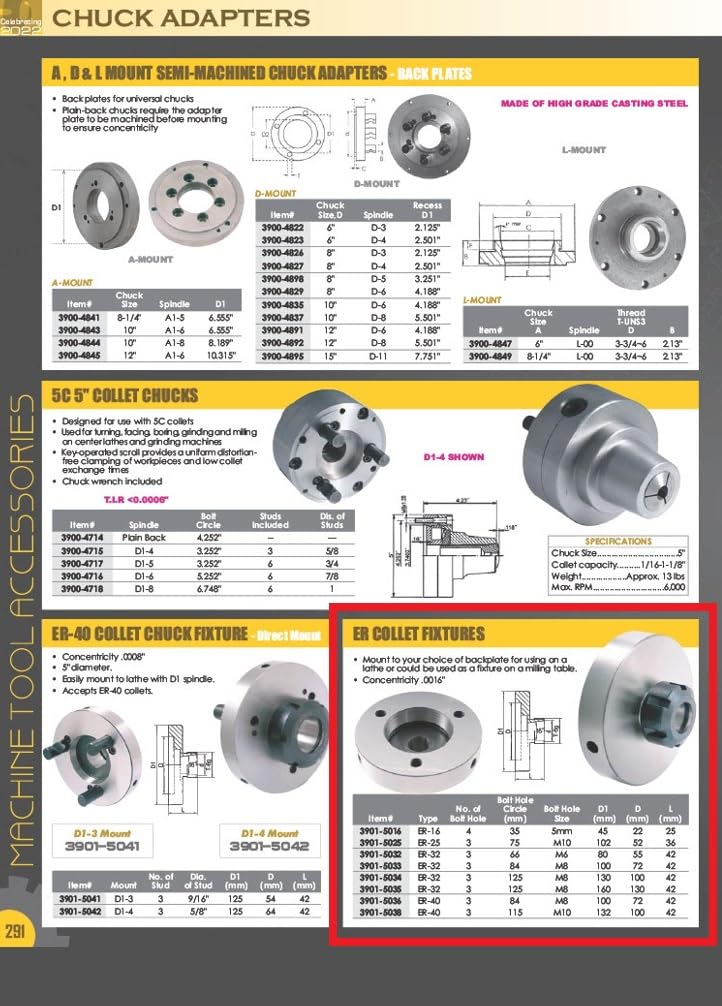

The HHIP 3901-5032 ER-32 Collet Chuck features an 80mm diameter and a precision concentricity of .0016", making it an essential tool for both lathe and milling applications. Its robust design ensures durability, while the included wrench enhances user convenience.

R**Z

Game Changer

I had originally purchased a collet chuck with MT3 from the Little Machine Shop. For accuracy, the MT3 chuck cannot be beat, but installing it through the spindle of the lathe was a PITA, which meant I rarely used it. This chuck is extremely well made and is easy to install (side note: There is a fantastic 3D printed tool you can find on Thingiverse for installing the small chuck nuts on the "Chinese" hobby lathe) and has less run-out than my 3 jaw (abut 1.5 tho). The fact you can remove and reinstall parts without losing much concentricity is really helpful to reverse a part and when spit balling a fit into a project. You will need to invest in a good set of all the ER32 collets, because I guarantee even if you lack one... that is the one you will need.

D**D

Fits the Grizzly G0765 mini-lathe perfectly

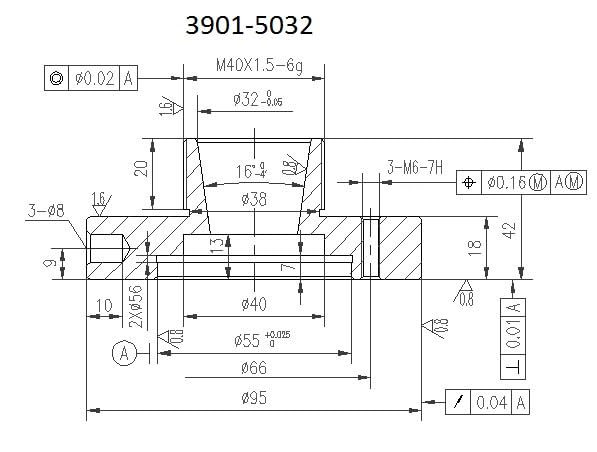

I appreciated the schematic included in the description photos. I would have had no way of knowing it would fit my lathe without it. I have a Grizzly G0765 7x14 mini-lathe that is the same size as many of the Chinese mini-lathes. This bolted perfectly right on the face plate. I gauged it to make sure it was running true, and it does. Mine came with a wrench, so no need to purchase one. The only thing I would change about it is some way to grip the base while using the wrench on the nut. It is slick and with an oil film on your hands and the base and no grooves to hold with a wrench it is hard to hold while turning the nut with the wrench. I solved this with an old oil filter wrench that I taped a couple of pieces of old inner tube to for grip. It holds the base tightly so I can wrench it tight or loose. Easy in and out on the collets, it does a great job and runs true. Happy with it and it stays on my metal lathe 90% of the time.

A**E

Great Chuck, OK Wrench

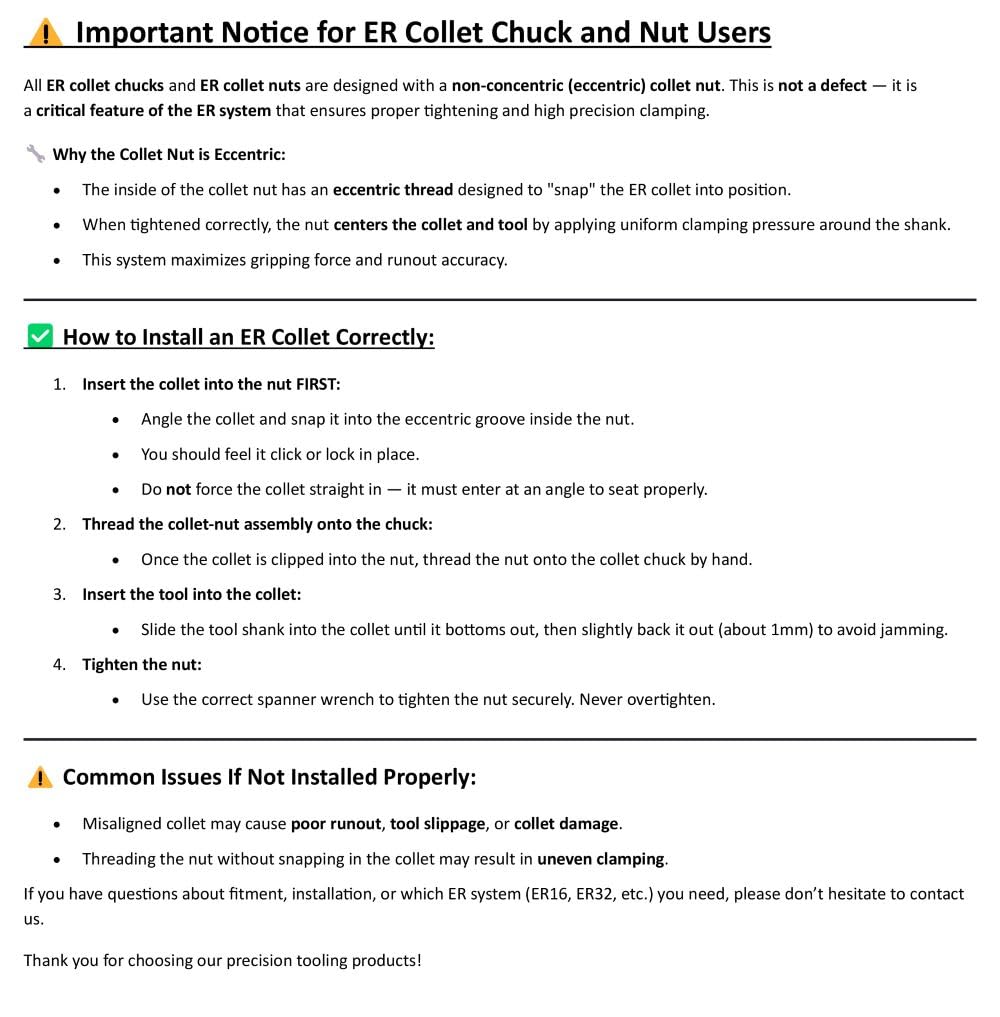

I saw a review that said, "It's a hunk of metal; hard to mess up" or something to that effect. There is a LOT that can be messed up on this piece. Concentricity, runout, accuracy, parallelism and surface finish all add up to make or break a piece of precision tooling. I didn't want to risk a bargain basement item not being accurate so I spent a little more and got a reputable brand.There are 3 holes in the edge of the chuck for a Tommy bar. Big plus! A 5/16" bar fit so an 8mm bar probably would also fit. It comes with a hook type wrench. The inside radius of the wrench is smaller than the OD of the ER40 collet nut so the wrench only contacts the nut at the notch and the other end of the radius. It looks like a good start to slipping off of the nut. Since the ER40 collets will be used on both the lathe and mill I'll be ordering a pair of the wrenches that have closed circle ends like https://www.amazon.com/uxcell-Collet-Spanner-Clamping-Non-slip/dp/B098JKMPG3/ref=sr_1_10?crid=27GW12BOWE1YL&keywords=er40%2Bwrench&qid=1701042827&sprefix=er40%2Bwrench%2Caps%2C101&sr=8-10&th=1.The whole point to me of using ER collets is the accuracy they offer. The collet chuck is very nice for the price. It has the usual issues of less than premium tooling. All of the drilled holes had sharp edges, quickly remedied with a Noga hand held countersink. The male threads for the nut looked perfect but to the fingers they were a little prickly. Literally two swipes with 320 grit emery cloth and they were smooth. The collet nut spins on very smoothly. I wasted no time getting it mounted on the lathe. I already had a backplate with a 72mm boss machined onto it so after a quick resurfacing the chuck was mounted. The screws required are M8x1.25 and with my backplate 35mm long would have been perfect. I used what was available; 40mm and they are about 3/8" too long but don't interfere with anything. I'll shorten them later. I immediately tested the runout with a dial test indicator inside the taper of the chuck and got almost no movement of the needle. There was so little that I would have to attribute it to the spindle bearings. That test completed, I snapped a 1/2" collet into the nut. The collet snapped in easily with a nice little click. Not having a test bar I chucked a 1/2" end mill into the collet, snugged it up and ran another runout test. The needle moved no more than .0002". I haven't made anything with the collets and chuck yet but have no doubt my accuracy should improve over the 5C collets I've been using.

J**N

Quality is an understatement

First off I am not a machinist by trade but... my Grandfather in the day had one of the largest machine shops in New England... I know what its like to hold a tenths.. With that said I ordered this adapter and used the standard screws that came with my lathe for the 4 jaw chuck and everything lined up perfect.. no visible play.. So I measured the outside adapter and only got 1 thou.. then I measured the nut on the spindle and that was 8 thou.. but its only the lock nut... Then I measured the inside and only out 2 tenths... I am waiting for the collet set to show up so I can chuck a pin and measure... but for what it is I could not be any happier.. So if you have a G0768 all you need is the 100mm version and should have everything else you need with the parts that came with the lathe...

I**Y

Works great!

This ER32 collet chuck fits perfectly on my Harbor Freight 7x10 mini lathe.Just used some M6 bolts and nuts to attach it.You really do have to drill a hole for a Tommy bar.I first used a center punch, then a pilot then a few bits to get to about 1/4".It’s the smallest steel rod I had. I turned the rod a little so it would fit the hole.Also knurled the top half. Probably not totally necessary but its makes griping it easier and looks nicer.I think its about 9-10" long. I wanted it long enough that it couldn’t rotate around the chuck.It’s a safety thing, no matter where it goes, it will hit something and not whip around.Note that it does come with a collet wrench but I would get a better one.I bought this one https://smile.amazon.com/gp/product/B01M6CKW3S/ref=ppx_od_b_detailpages00?ie=UTF8&psc=1I am very happy with it.

M**R

Poor finish hhip 3901-5033 poor finish.

I would not send this product to a customer knowing that the finish is not up to standards. Quality control ? I have other HHIP product that are 4.5 ⭐ . The weight is lighter on one side because it's missing metal. But other than that the rest of the finish is top notch. I'm giving 2 star because of the finish. Unhappy with the finish . Will cause vibrations because it's not balanced due to the improper finish

Trustpilot

1 month ago

1 week ago