Some deliveries may take a little longer than usual due to regional shipping conditions.

Customer Services

Copyright © 2025 Desertcart Holdings Limited

⚙️ Master metal with precision and power — don’t get left behind!

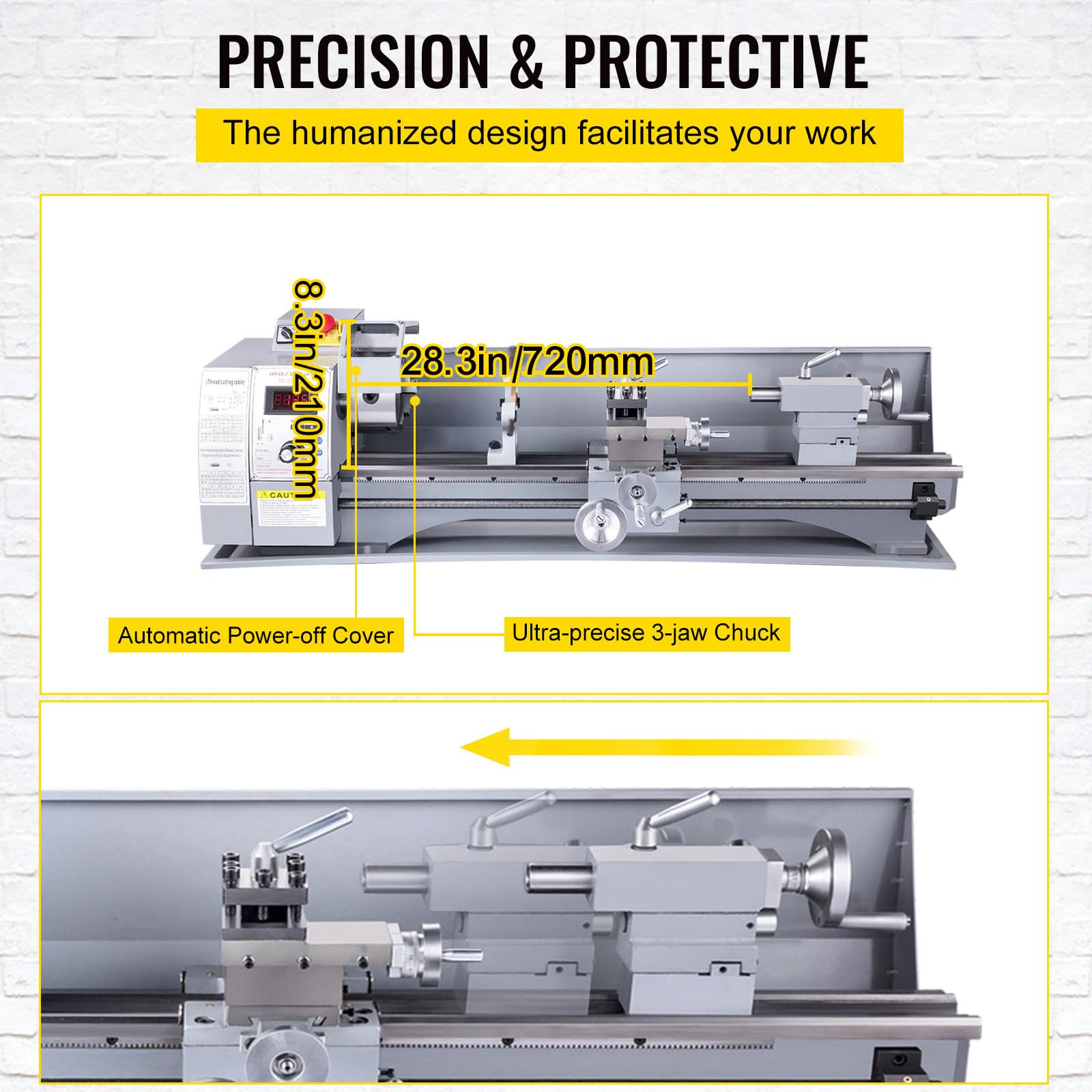

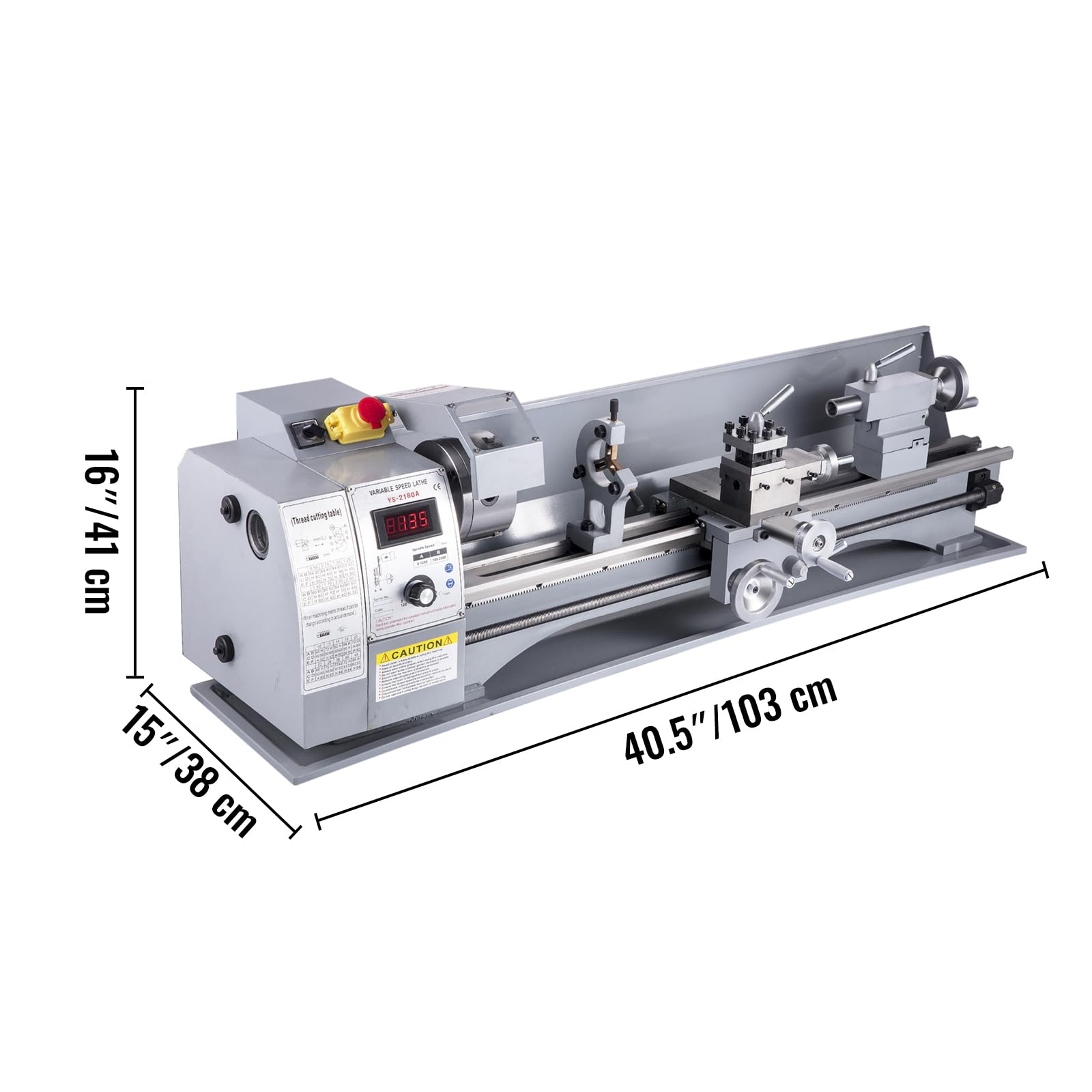

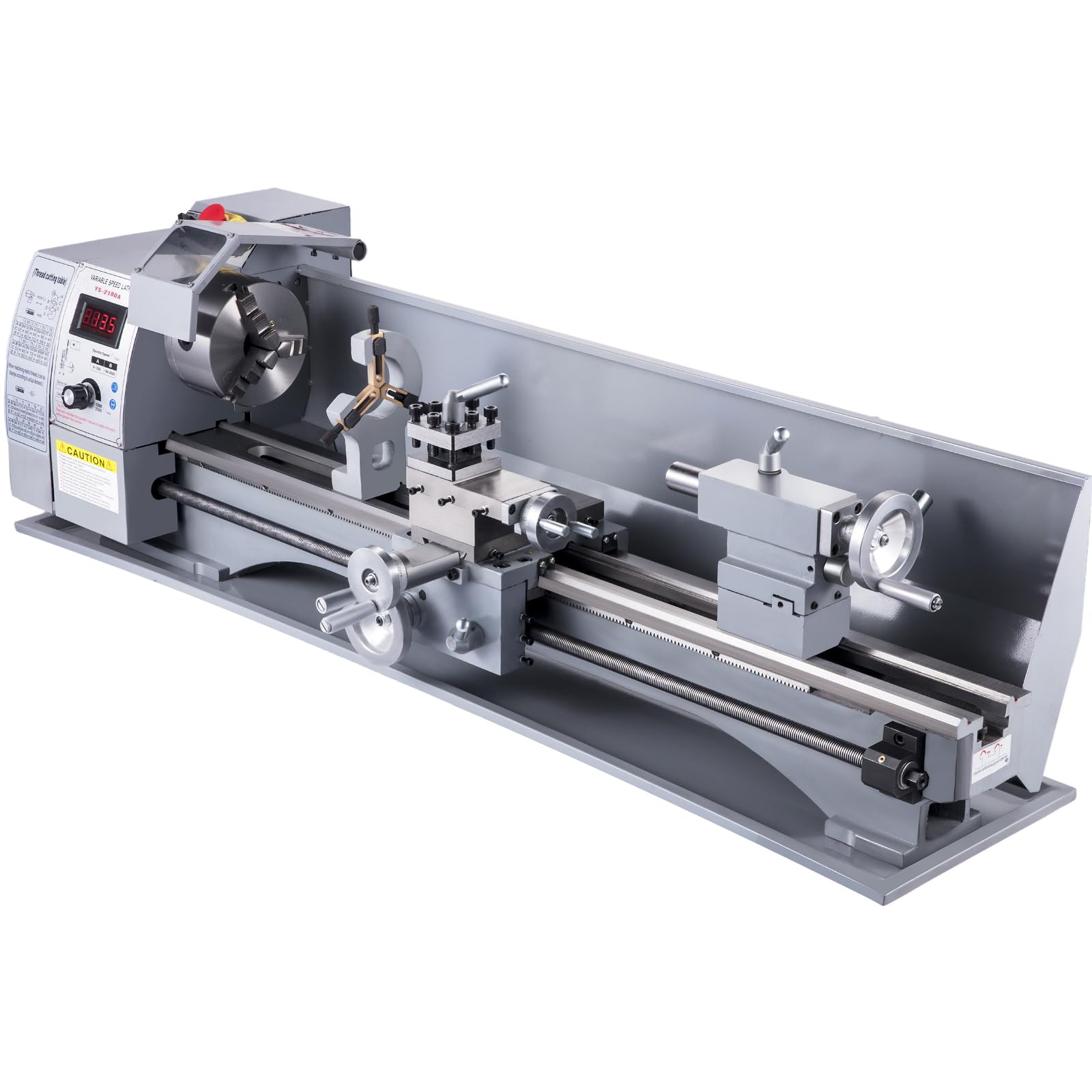

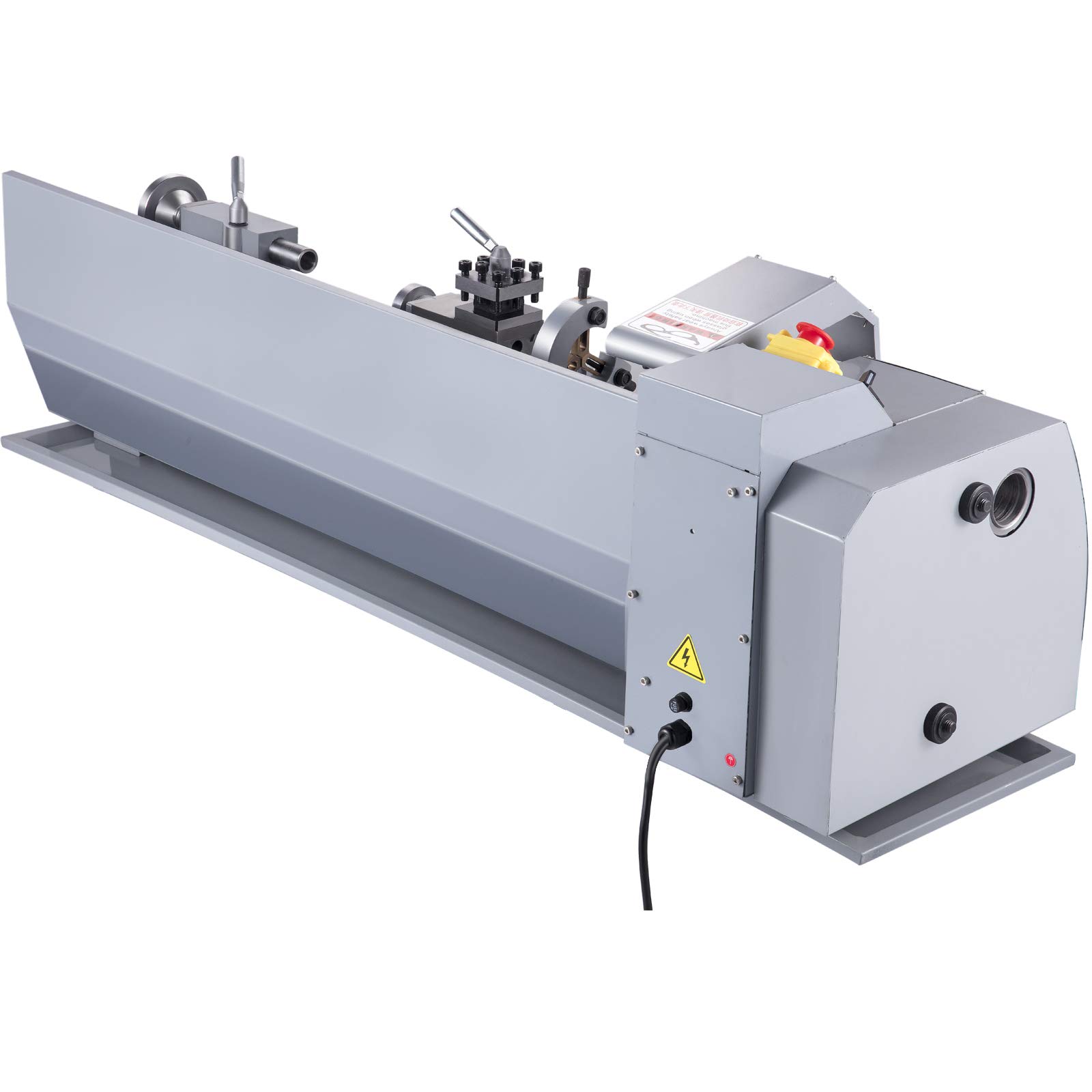

The VEVOR Metal Lathe 210x720 is a compact, precision mini lathe featuring a 750W brushed motor, variable speed control up to 2500 RPM, and a durable HT200 cast iron construction. Designed for metalworking enthusiasts and professionals, it offers a 3-jaw chuck, turret post for quick tool changes, and a stable bed for accurate turning of various metal parts. Despite mixed user feedback on motor type and alignment, it remains a versatile tool for small-scale metal projects.

| ASIN | B09S5JQ56T |

| Batteries Required? | No |

| Best Sellers Rank | #980,344 in Tools & Home Improvement ( See Top 100 in Tools & Home Improvement ) #55 in Power Metal Lathes |

| Customer Reviews | 2.6 2.6 out of 5 stars (36) |

| Date First Available | February 10, 2022 |

| Included Components | Metal Lathe |

| Item Package Quantity | 1 |

| Item Weight | 178 pounds |

| Item model number | Metal Lathe 210x720 |

| Manufacturer | VEVOR |

| Part Number | DLJSCC210JCK800MMMC |

| Power Source | DC |

| Product Dimensions | 48 x 19 x 18 inches |

| Style | 210x800 |

M**”

The worst lathe and company to deal with!

I wish I could post the whole back and forth conversation with this company about this lathe that I received. It was a horrible experience and I finally settled for a partial refund and kept the useless lathe after they wore me down over a period of a month and a half. I was tired of dealing with this company and reported them to Amazon. The first time I've ever had to file an AtoZ Guarantee complaint. The lathe was delivered a week late, it was completely out of spec with a headstock misalignment issue that could not be fixed without remachining/repairing the bed and recutting the seat of the headstock to properly align. A precision fix would have cost more than the purchase price. In addition what should have been a knew precision machine had rust and a pitted rail bed. It honestly looked like a poorly refurbished item that had seen years of use, definitely didn't appear new! The misalignment was .035 inches vertical (.889mm) and .045 inches (1.143mm) horizontal on a 9 inch travel. No where close to being right. This may not sound like much to the average person, but it completely rendered the lathe useless because each and every part that was turned would have had a taper that would have made any parts made on it completely useless. The seller refused to replace or refund and wanted me to pay for shipping to return this to them. That would have cost nearly 1/3 of the purchase price of the lathe because it would have to have been shipped back via freight just like it was shipped to me! They refused to provide a refund and arrange for shipping back to them and offered solutions for me to fix the lathe on my own. They low balled me on the refund FOR OVER A MONTH until I finally settled with them for 2/3 of the purchase price and keep the lathe! The repairs and adjustments they suggested were complete nonsense! They said they had adjustment screws for the headstock alignment, but there was nothing available except the mounting bolts! They didn't even know their own product! They suggested shimming the headstock but in order to do that it would have had to have been shimmed over 1/4 of an inch which meant the headstock would not have been resting properly on the bed! This would have caused a possible hazard because if you're turning steel, a head crash could have caused the entire headstock to possibly move, shearing the mounting bolts and send metal fragments flying! Shimming the headstock would have been fine if it had only been a couple thousandths out of alignment but even then, anyone that has ever done any serious machining knows that this isn't the RIGHT way to fix this and since it was in warranty and was delivered out of spec the seller/manufacturer should have backed up their product! Do not deal with this company! And by the way the seller BOBORAN is the company VEVOR, so I was dealing straight with the manufacturer. Save your money and go with a better lathe if you need one this size. Don't buy anything from VEVOR unless you're willing to spend additional money to fix it! Worst experience with any seller/company/manufacturer ever!

C**.

A Diamond in the ruff

I ordered this Lathe after months of reading reviews, watching various manufacturers and models on U-Tube, viewing feedback on the various websites, etc. This Lathe is listed as the Vevor version with the 850 Watt brushless motor. I have a mechanical background and have been using tools and equipment in and out of the shop for upwards of fifty five years, from what I was reading and seeing the majority of the issues listed are the same you would have with setting up any precision machine. Knowing that, and the fact it had the brushless motor option, was the one major factor for choosing to purchase this model from Vevor as reported by all users the brushed motors will barely perform in a 7" X 10" lathe let alone a 8" 200X800 bench top beast. I was pleasantly surprised that the manual included with the lathe said in fact that this lathe is powered by a 1100 Watt brushless motor - even better or so I thought. Pics attached. It arrived in due time with some forklift damage to the shipping package clearly noted by the shipper and me, the damage to the lathe was mostly in the back splash area. My son gave me a hand mounting her to the bench, good and level ready for a good cleaning. The lathe had a good coat of cosmoline, No rust Good, No metal filings or grinding debris, Good. What is this Behind the motor cover? A small brushed DC motor, brush caps, and a equally small DC motor Controller board! What? No brushless motor? I honestly wonder how many Vevor customers think they bought a lathe with a brushless motor in their Vevor products? I contacted Vevor directly and was told in writing "to date as of March 2023. None of our lathes have ever had a brushless motor Not a single one!" They also said "750 watt brushed motor is standard equipment for this Lathe". Their misleading ads... No assets in the USA... The good part whoever built this lathe and assembled it, did it like they were working in pre return to China Hong Kong! Hats off to them! Everything was in the box, metal gears, center rest, Live center, center. Ways are properly ground and true. Chuck run out perfect. The only real issue besides the motor is the the indicator for the slide rest is on back of the saddle with no indicator or alignments marks whatsoever which is really strange? How are you supposed to see it if it did have an indicator? stand behind the lathe? There are a few casting flash here and there, minor paint overspray and of course the terrible performance from the little DC Brushed motor that belongs in a manual treadmill of something that doesn't require a motor at all. The finishes I have achieved are probably a seven out of ten. The DC motor struggles on even the smallest of cuts. The travel speed is way too fast even when using the slowest combination of leadscrew gears. The Vevor manual says they will honor a one year warranty for defects in material and workmanship when used as intended. Hopefully my Vevor motor and board will last that long. I'm pretty sure engineering underrated components for a precision machine qualifies as a defect in poor workmanship and design? If I do decide to keep it plans for the brushless motor and controller will be at the top of the minimum required parts to repair this lathe list..

Trustpilot

3 days ago

2 months ago